Get Your Free Quote…!

We are one of the leading Laboratory Fume hood manufacturer, supplier and exporter in India. Our offered laboratory fume hood is made using quality raw materials and tested under strict supervision of quality professionals. Regardless of its name—Fume Hood, Laboratory Fume Hood, Chemical Fume Hood, Fume Cabinet, Fume Cupboard, Laminar Fume Hood, Fume Closets, or any other—the safety of the lab staff is its primary role. If your experiment involves anything hazardous—harmful gases, the potential for explosion, the potential for spillage, smoke, or sparks—conduct it within a fume hood. You will be secured from gases and other unintended consequences of your biological or chemical operations.

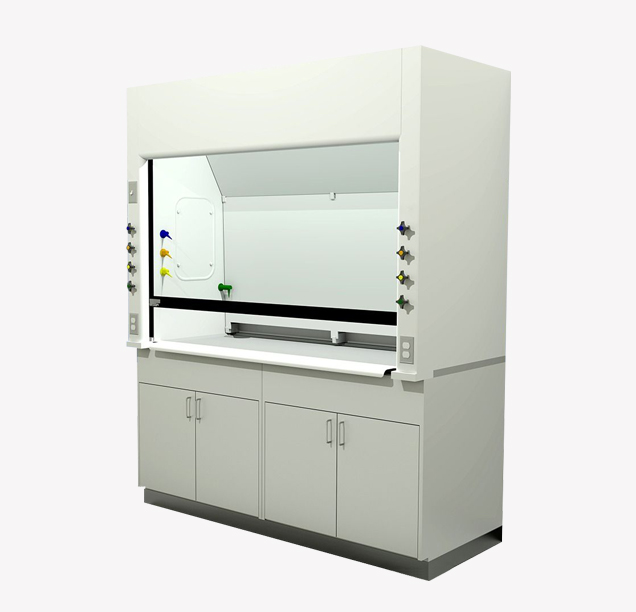

A fume hood, also known as a fume cabinet, is a form of ventilation equipment used in laboratories to reduce exposure to poisonous or dangerous fumes, gases, dust, and vapours.In a laboratory for conducting chemical processes, a laboratory fume hood is the single most important element. A fume hood, also known as a lab hood or a chemical hood, shields workers from dangerous compounds they might inhale. The sash, a transparent movable screen on a fume hood, protects employees from splashes and spills that could happen inside the laboratory fume hood. The mainstay of laboratory exhaust systems, fume hoods are the most used method for local ventilation. Swastik is a leading laboratory fume hood manufacturer in India. We offer a wide variety of fume hoods for your labs, so whether you need one for research and development, quality control, education, or outside testing, we make all type of fume hoods available.

When using a fume hood, air is drawn into the chamber with the help of a blower from away from the user. The facility exhaust system is used by the fume hood to cleanse the air before venting it outside. An alternative is to use a laboratory fume hood to filter the air, get rid of any harmful fumes, and then circulate the air inside the space. Most laboratory fume hoods have gauges or sirens that can alert the user to inadequate airflow and the possibility of being exposed to dangerous vapours.

Scientists conduct numerous experiments in laboratories, some of which can be hazardous. Gases that are poisonous to breathe are a constant issue in chemistry labs. Laboratory Fume hood is the equipment that provides effective solution in this situation.

Laboratory Fume hood reduce the possibility of exposure to poisonous gases while allowing lab workers to operate with potentially hazardous chemicals. The sash (window) of a chemical hood enables the worker to observe and operate objects inside the enclosure while preventing fumes from dangerous or volatile chemicals from coming into contact with the worker's face.

The best way to cut down on energy expenditures is to keep the sash as minimal as possible and shut when not in use. The facility's HVAC system is put under less stress since less exhaust is produced because the laboratory fume hood discharges conditioned air that has either been warmed or cooled, in accordance with the local environment.

Remember that the position of the sash can change the enclosure's air velocity, and a locked sash may have sufficient additional airflow to disrupt delicate components or instruments. In order to achieve the balance that is right for you, the blower rate may need to be adjusted slightly.

Need Laboratory Fume Hood for your project? Our experts are able to help with your process system. Known as a top laboratory fume hood manufacturer in India, we provide efficient fume hood solution to suit your requirement.To help you find the fume hood that best suits your requirements; contact one of our applications engineers now. For additional details and a free proposal, get in touch with us.

| Type of Fume Hood | Overall dimension | Inner dimension | Worktop height | ||||

|---|---|---|---|---|---|---|---|

| L | W | H | L1 | W1 | H1 | H0 | |

| Bench Type Fume Hood | 1200 | 915 | 2300 | 1000 | 645 | 1250 | 900 |

| 1500 | 915 | 2300 | 1300 | 645 | 1250 | 900 | |

| 1800 | 915 | 2300 | 1600 | 645 | 1250 | 900 | |

| 2100 | 915 | 2300 | 1900 | 645 | 1250 | 900 | |

| 2400 | 915 | 2300 | 2200 | 645 | 1250 | 900 | |

Valves : Panel mounted valves with color coded as per DIN/BS standard remote knobs fitted on front vertical post

Cup Sink : Oval shaped, Single piece molded polypropylene (PP) in standard offering. Solid Epoxy cup sinks can also be provided as per end user requirement on request.

Nozzles : For greater flexibility of use, taps are tapered in tubing of size from with flexible tub-ing of sizes from 1/4" to 1/2".

Storage : Provided below the fume hood in GI construction. There are enough space for storage.

Electrical Utilities : Provided below the fume hood in GI construction. Factory wired electrical. sockets and switches. Fire retardant wires. Built-in starter for blower.

Apparatus Grid : Optional structure for attaching and suspending laboratory equipment.

Heavy duty Gl construction : Compared to MS CRCA, GI offers you superior chemical, Corrosion and scratch resistance. Durable epoxy powder coating: products are powder coated and thoroughly tested for reliability.

Vertical Rising Sash : Made of toughened Float Glass for impact resistance. Smooth and light sash operation on timing belt.